Practical, Operational,

and People-Focused

At RNG Krishna, sustainability is approached as a function of efficient manufacturing rather than a separate initiative. The focus is on reducing waste, improving material efficiency, and extending resource value. Packaging materials, cartons, and plastics are routed through responsible recycling partners wherever possible.

Operational Sustainability Practices

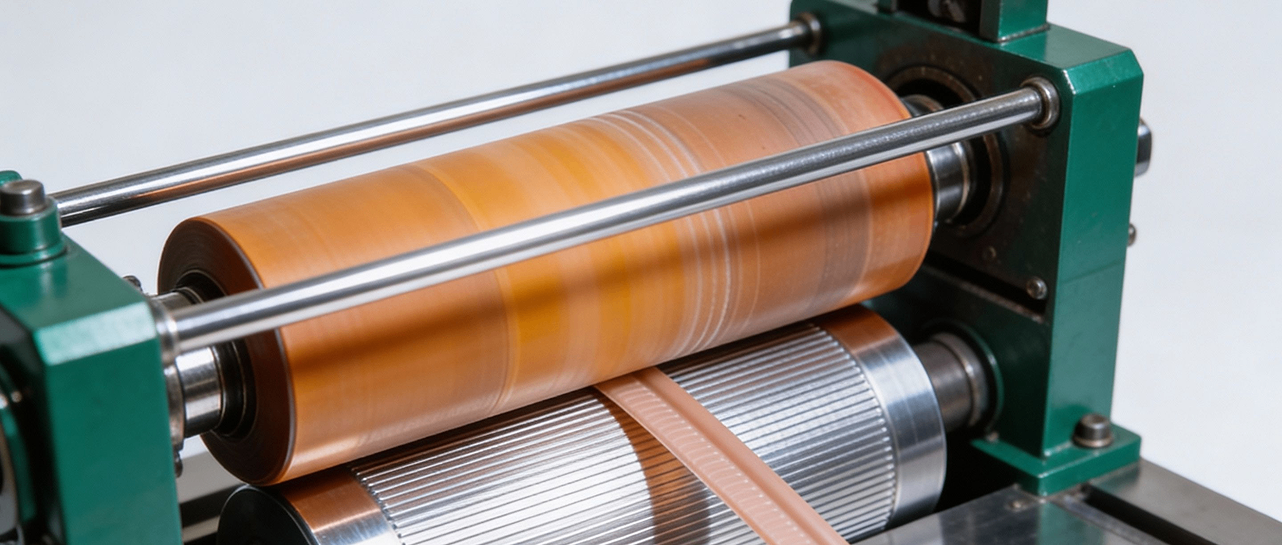

Materials that can be reused or recycled are systematically segregated within the factory workflow. Packaging materials, cartons, and plastics are routed through responsible recycling partners wherever possible. Controlled production parameters reduce rejects and rework, lowering overall material consumption. Engineered synthetic coated webbing platforms further support non-leather, cruelty-free product programs across belts and equestrian categories.

Ethical Production

Standards

Responsibility at RNG Krishna extends beyond materials to include the working environment and daily factory practices. Large windows and natural light are incorporated across production areas to improve visibility and reduce dependency on artificial lighting. Ventilation systems and exhaust fans help regulate temperature and maintain air quality across the facility.

Our Commitment

Zero animal-derived materials

Engineered platforms support cruelty-free programs across all product categories.

Waste segregation & recycling streams

Packaging and plastics are routed through responsible recycling partners.

Energy-efficient equipment & lighting

Natural light and ventilation reduce dependency on artificial lighting and climate control.

Regular safety & hygiene audits

Cleanliness and safe material handling support workforce well-being and stable operations.

Workplace Excellence and Culture

Cleanliness and hygiene practices are maintained across all zones to support consistent production conditions and workforce well-being. Clearly defined workspaces and safe material handling processes contribute to an organised and disciplined factory environment. These practices enable stable operations, consistent output, and a working culture aligned with long-term manufacturing excellence.