Engineered for Goodyear

and Fashion Footwear

To deliver footwear welts engineered for dimensional stability, material consistency, and repeatable performance across global footwear manufacturing programs. Each stage, from material formulation to final output, is designed to ensure that approved samples scale reliably into production without variation across repeat orders.

RNG Krishna’s manufacturing approach addresses these challenges through disciplined production control. Any variation can affect stitching accuracy, longevity, and final assembly. From stabilised raw material formulation to fabrication and finishing, each stage minimises variation across production runs, ensuring predictable performance and dimensional accuracy.

Process Stability

Direct granule-based manufacturing ensures uniform material behaviour across extended production runs, minimising variation between sampling and bulk execution.

Versatile Stitching

Our system provides comprehensive support for both stitched and unstitched weld constructions, catering to the rigorous demands of traditional Goodyear welted boots and high-end fashion footwear.

Single-Source Execution

End-to-end in-house production reduces dependency on multiple suppliers, improving coordination, traceability, and supply reliability.

Manufacturing Capabilities

Footwear welts are manufactured entirely in-house using controlled extrusion systems designed for Goodyear-welted construction and fashion footwear. Production parameters are monitored to ensure consistent integration into modern footwear assembly lines.

Quality & Scalability

Scalable Production Infrastructure

Dedicated sampling and production pods enable parallel development and controlled scale-up. Manufacturing systems support repeatable execution for export programs, with a capacity of up to 300,000 metres per month.

Frequently Asked Questions

RNG Krishna footwear welts are designed for both Goodyear-welted construction and fashion footwear, ensuring compatibility with modern footwear assembly processes.

Consistency is achieved through direct granule-based production, controlled process parameters, and in-house quality checks aligned with AQL inspection standards.

Yes. Profile geometry, thickness, width, and colour configurations can be customised based on approved samples and specific end-use requirements.

Manufacturing systems support repeatable export execution with controlled capacity of up to 300,000 metres per month, ensuring reliable long-term supply.

We know that every decision has an impact

Sustainability

We look beyond sustainable construction with a holistic approach to corporate social responsibility that addresses partners, people, projects, practices and places; our 5P Model.

Quality

We see projects through and proactively develop solutions to exceed expectations. Operational excellence instills quality principles that tangibly demonstrate success.

Passion. Integrity. Hard work. Professionalism. Caring.

These core values have been with us since the beginning, and they’ve infused who we are and how we build. Nothing brings us more excitement than transforming the skyline — and we do it by setting our standards high, striving for the best, building trust, and lifting up the people around us.

Your next-generation construction partners

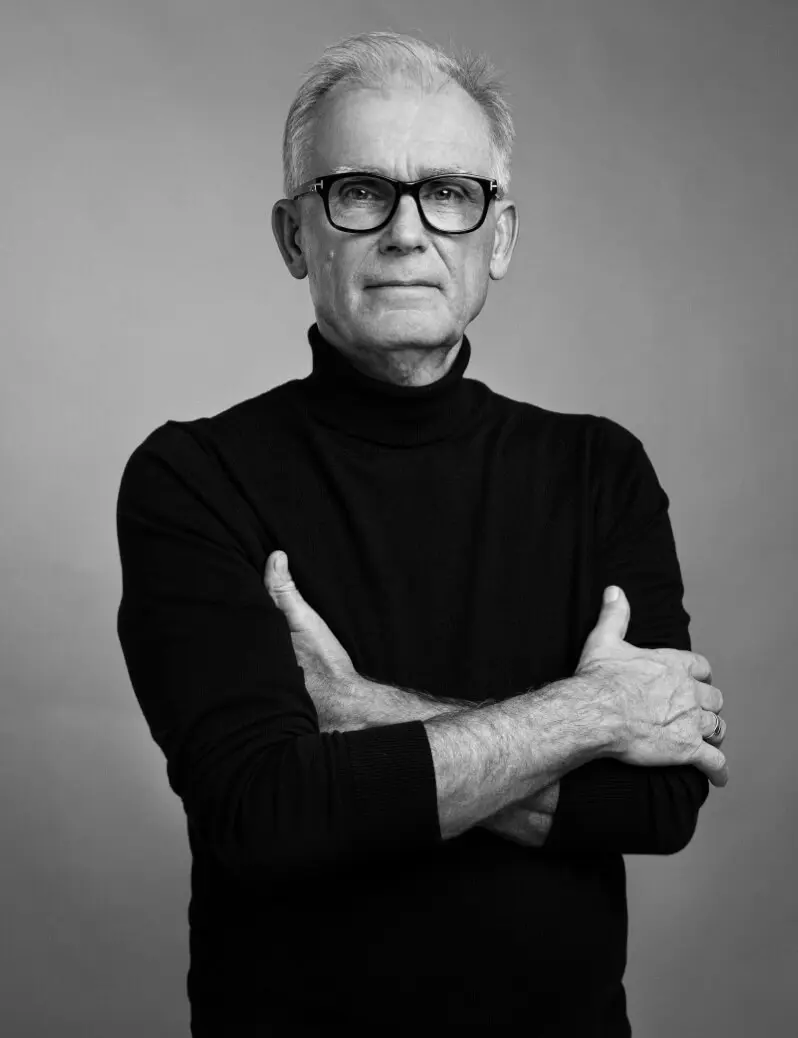

Akarsh Garg & Utkarsh Garg

Directors

“Manufacturing is ultimately about people. The people who build, the people who partner, and the people who rely on consistency every day.”